Intelligent Robotics Software for Real-World Performance

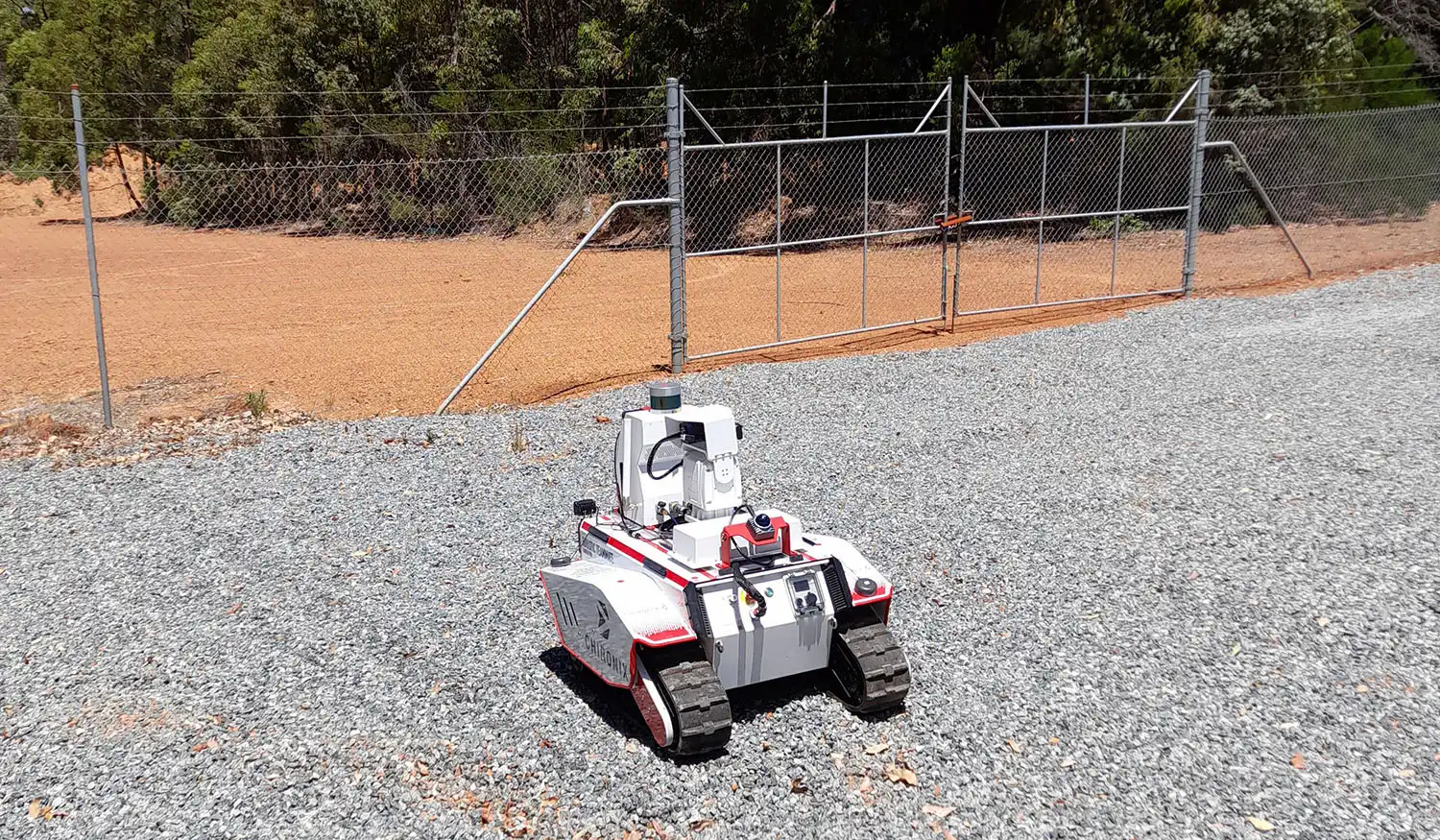

PilotOS is the powerful, intuitive software platform that drives the world’s most advanced robotic systems, ensuring efficient collaboration between human and robot teams.

Engineered for precision, speed and adaptability, PilotOS empowers teams to work smarter and achieve more while keeping workers safe.

Compatible with all ROS-operated platforms, PilotOS is the only robotics software that offers total flexibility – allowing you to choose the perfect robot for any task.

Scalable Automation That Delivers Real Value

Lift Team Performance

Increase Efficiencies

Improve Safety

Clearer Insights, Better Decision Making

Reliable Autonomous Inspection

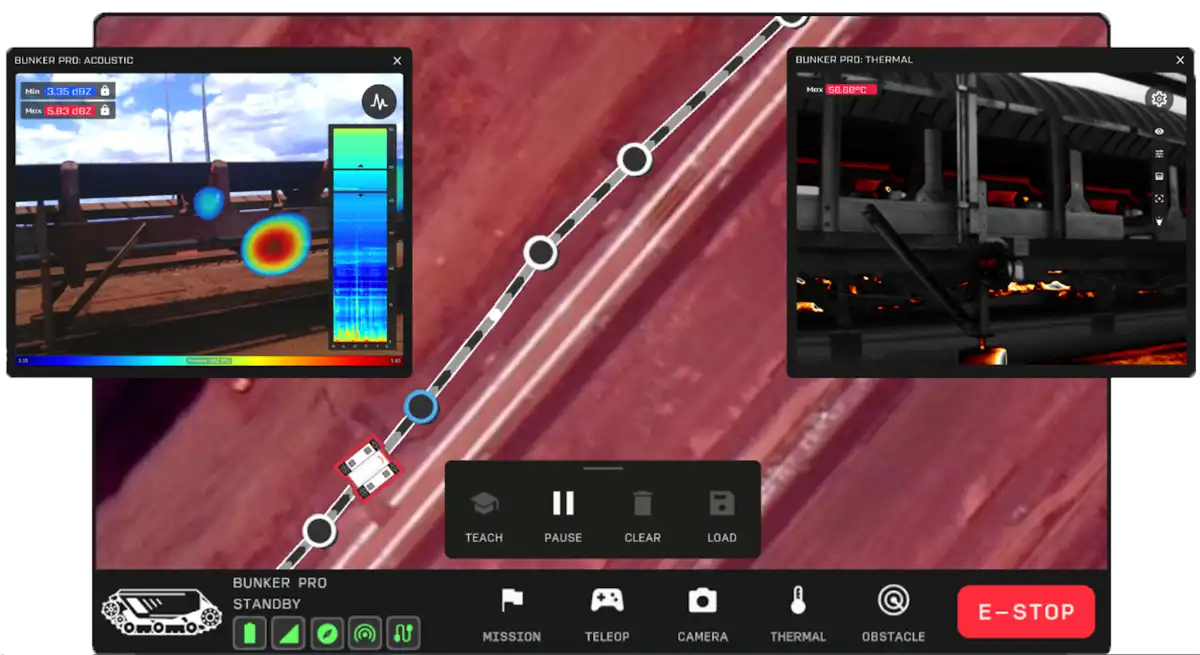

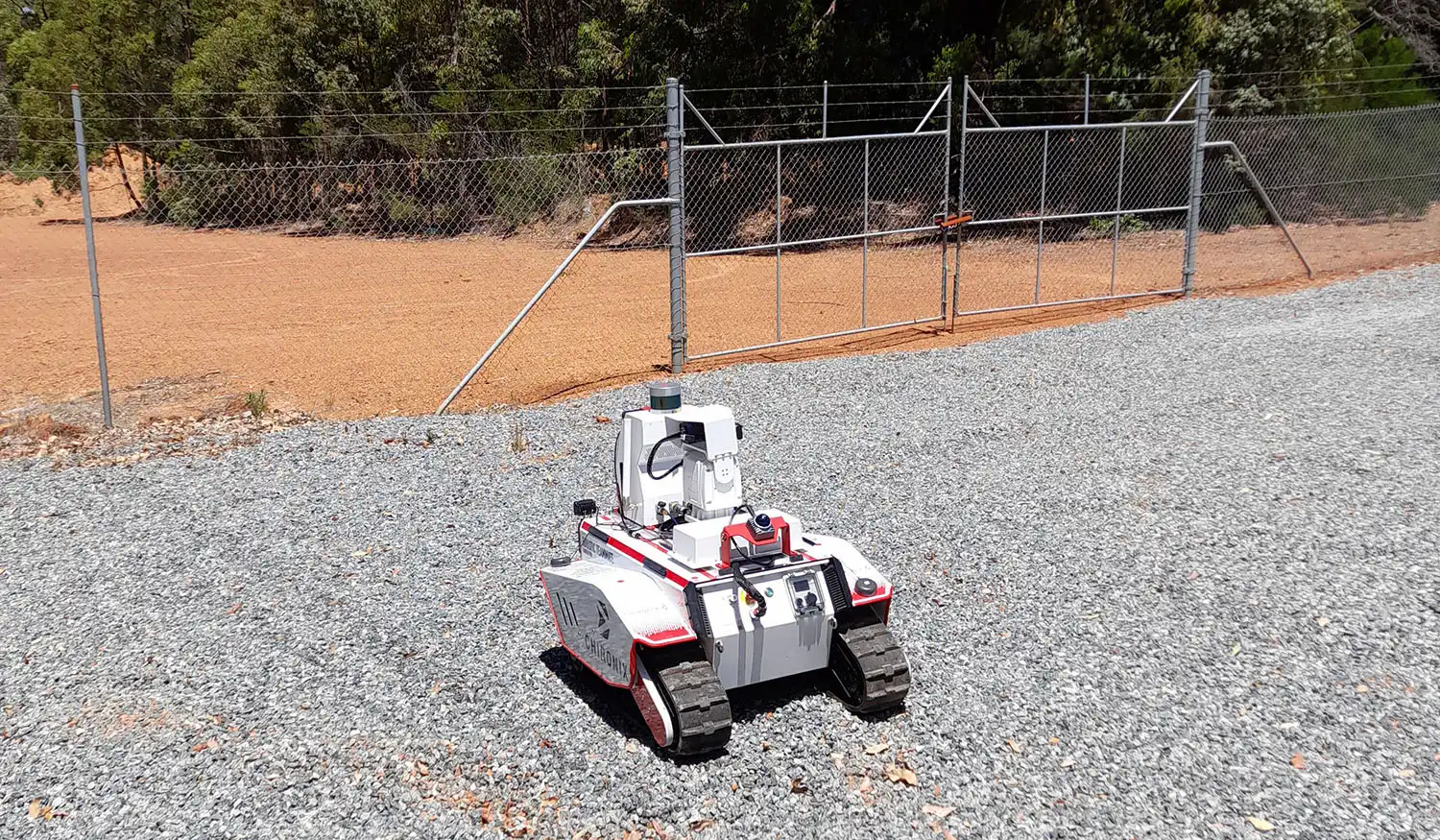

PilotOS enables remotely controlled, around-the-clock, high-quality asset inspections and monitoring, detecting anomalies and alerting operators to potential risks before they turn into failures. Stationing a robot onsite allows for continuous or on-demand inspection, reducing the need for costly, time-consuming manual checks.

Simple, Adaptive Navigation

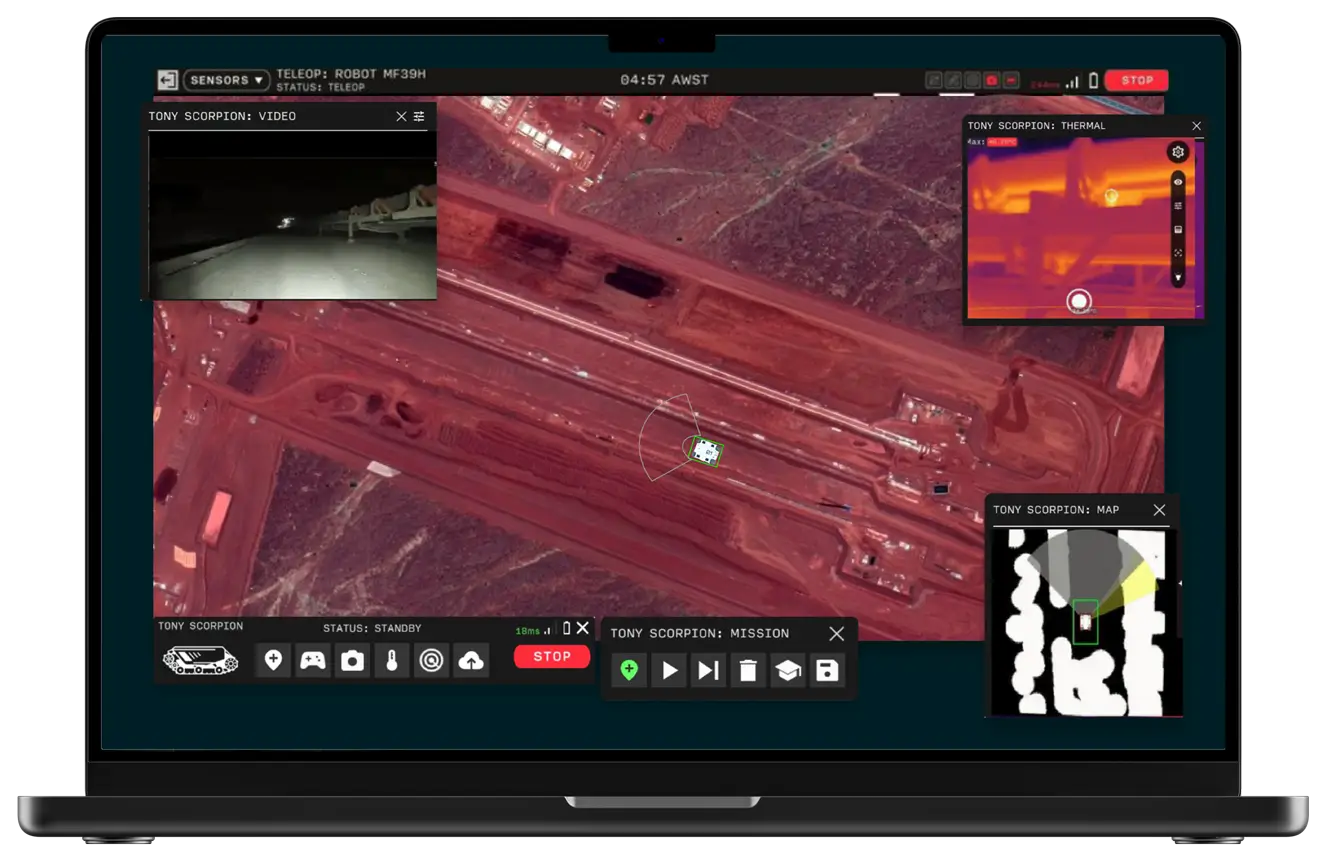

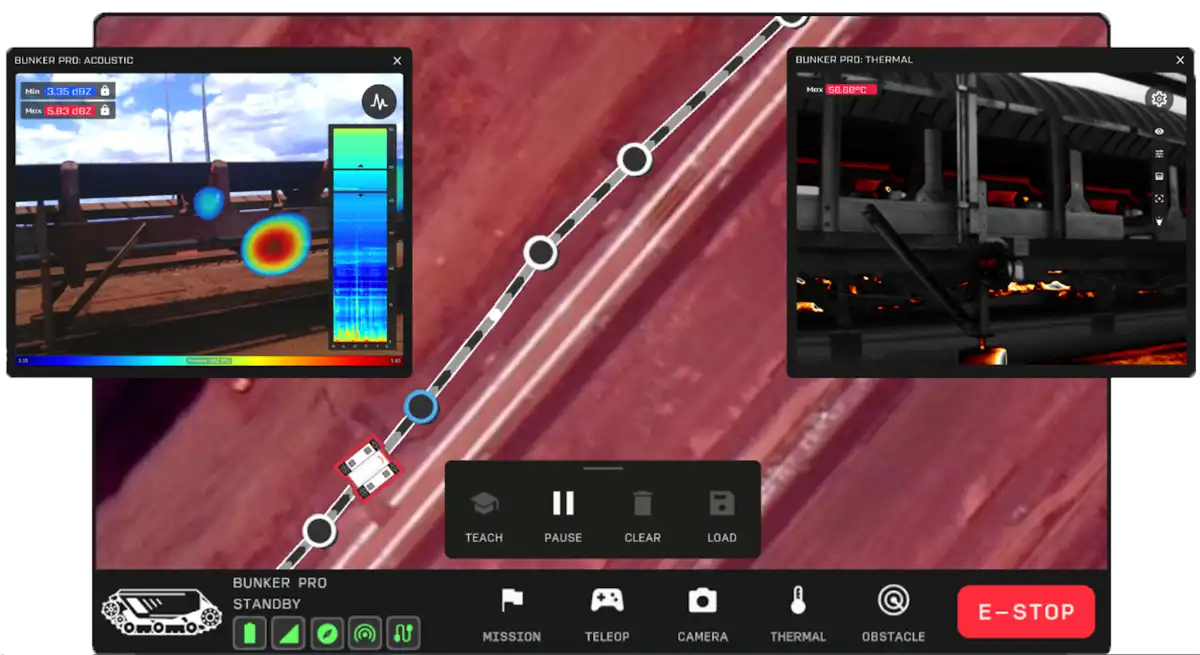

PilotOS delivers precise navigation, allowing robots to maneuver through complex environments, avoiding obstacles and adapting to real-world challenges. Operators maintain awareness with GPS tracking, live video and 2D LiDAR mapping. Use pre-set routes or adjust paths on the go for ultimate flexibility, while follow-the-leader mode allows field personnel to guide robots using simple hand signals.

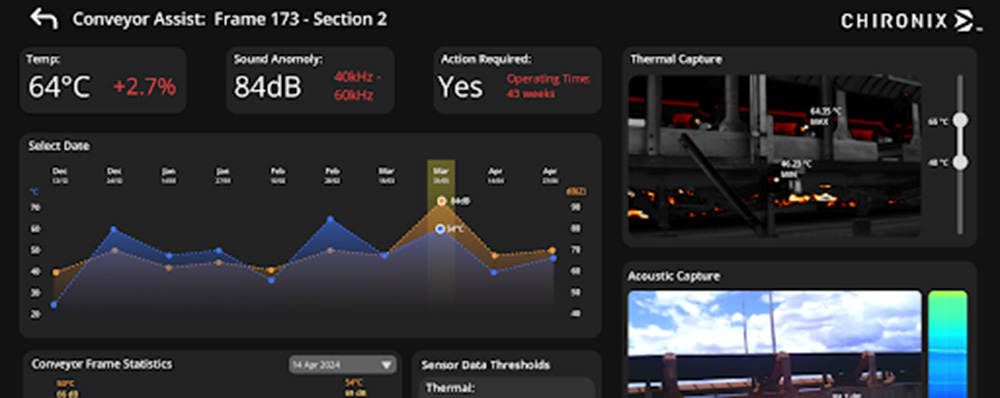

Powerful Data Capture

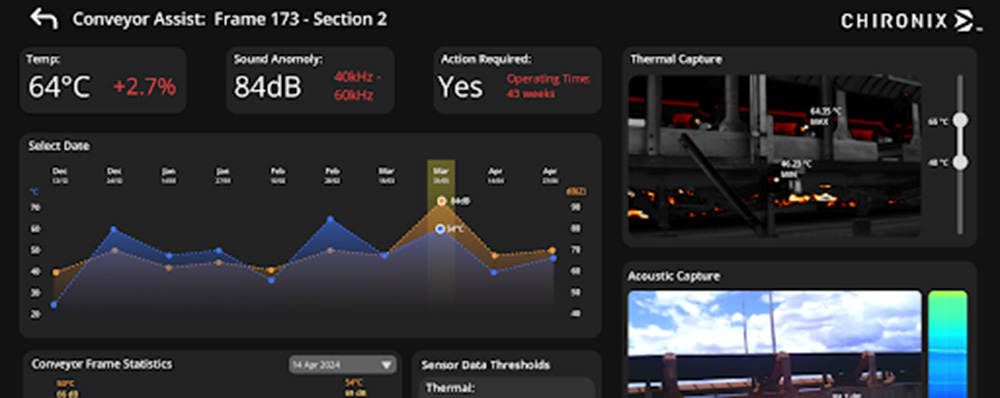

PilotOS-enabled robotics allows you to see, hear, sense and analyse better than your best inspectors. Advanced thermal, acoustic and visual sensors provide detailed data, detecting anomalies before failures occur. Historic data reporting and real-time visibility enable better decision-making.

Unlock Valuable Insights

Real-time sensor fusion and analytics turn robot data into operational intelligence. Monitor equipment health, detect anomalies early, and make informed decisions about maintenance and operations. PilotOS doesn’t just collect data – it helps you understand what that data means for your business.

Manage All Of Your Robots At Once

Oversee multiple robots across multiple sites from a single, intuitive dashboard. PilotOS simplifies fleet coordination, enabling remote tasking, monitoring and system-wide optimisation. Scale effortlessly as your operations grow, ensuring efficiency and maximum return on investment.

PilotOS enables remotely controlled, around-the-clock, high-quality asset inspections and monitoring, detecting anomalies and alerting operators to potential risks before they turn into failures. Stationing a robot onsite allows for continuous or on-demand inspection, reducing the need for costly, time-consuming manual checks.

PilotOS delivers precise navigation, allowing robots to maneuver through complex environments, avoiding obstacles and adapting to real-world challenges. Operators maintain awareness with GPS tracking, live video and 2D LiDAR mapping. Use pre-set routes or adjust paths on the go for ultimate flexibility, while follow-the-leader mode allows field personnel to guide robots using simple hand signals.

PilotOS-enabled robotics allows you to see, hear, sense and analyse better than your best inspectors. Advanced thermal, acoustic and visual sensors provide detailed data, detecting anomalies before failures occur. Historic data reporting and real-time visibility enable better decision-making.

Real-time sensor fusion and analytics turn robot data into operational intelligence. Monitor equipment health, detect anomalies early, and make informed decisions about maintenance and operations. PilotOS doesn’t just collect data – it helps you understand what that data means for your business.

Oversee multiple robots across multiple sites from a single, intuitive dashboard. PilotOS simplifies fleet coordination, enabling remote tasking, monitoring and system-wide optimisation. Scale effortlessly as your operations grow, ensuring efficiency and maximum return on investment.

Robots That Speak Your Language

At Chironix, we understand that for robots to effectively work alongside humans, communication is key. That’s why we’ve reimagined how humans and robots interact.

Our multidisciplinary team of engineers, psychologists, designers and even artists customises communication methods that go beyond basic commands.

Our robots not only recognise voice and gestures but also respond intuitively, using visual, tactile and audible cues to communicate understanding. We also employ wearable devices that share robot vision and vibrate in sync with a robot’s direction and proximity. This ensures a safer, more efficient collaboration that drives better outcomes for every team.

Explore Pilot-OS

Ready Platforms

Inspection Platforms

Logistics Platforms

Security Platforms

Quick to Deploy,

Ready to Perform

Frequently asked questions

Unlock the Power of Robotics. Let’s Talk.

Contact us today to explore how PilotOS can transform your operations.

Head Office

Unit 3/33 Millrose Dr,

Malaga

Western Australia 6090

US Office

Suite 200

1703 Pennsylvania Ave

Washington DC

20006 USA