Streamline Your Mining Operations

Improve safety and boost productivity with advanced automation. Our robotic systems are designed to work alongside your team, capturing critical data in remote and high-risk mining environments.

With continuous monitoring and real-time insights, you’ll stay ahead of maintenance issues, prevent costly failures and enhance efficiency – no matter the terrain or conditions.

Optimise Predictive Maintenance & Maximise Uptime

Automate Inspections

Precise Data Collection

Prevent Downtime and Failures

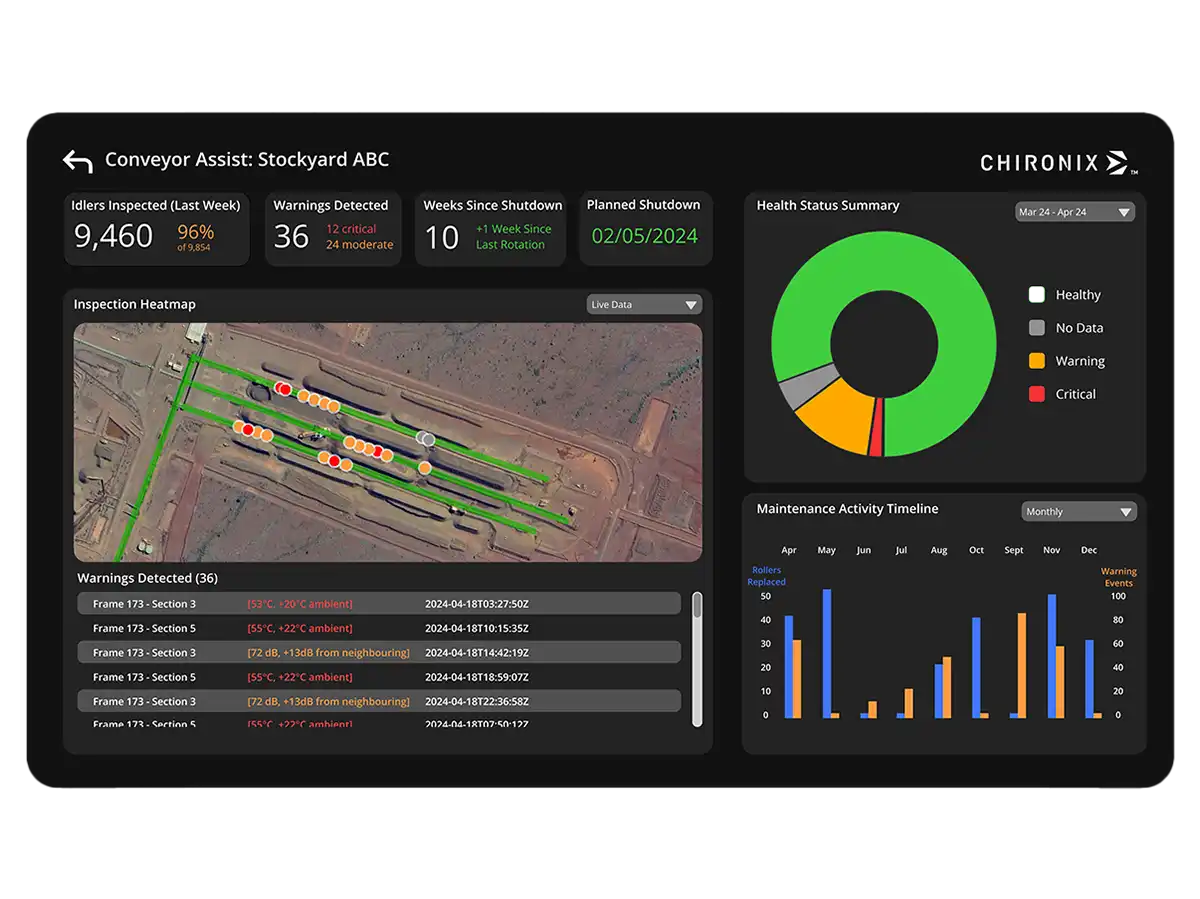

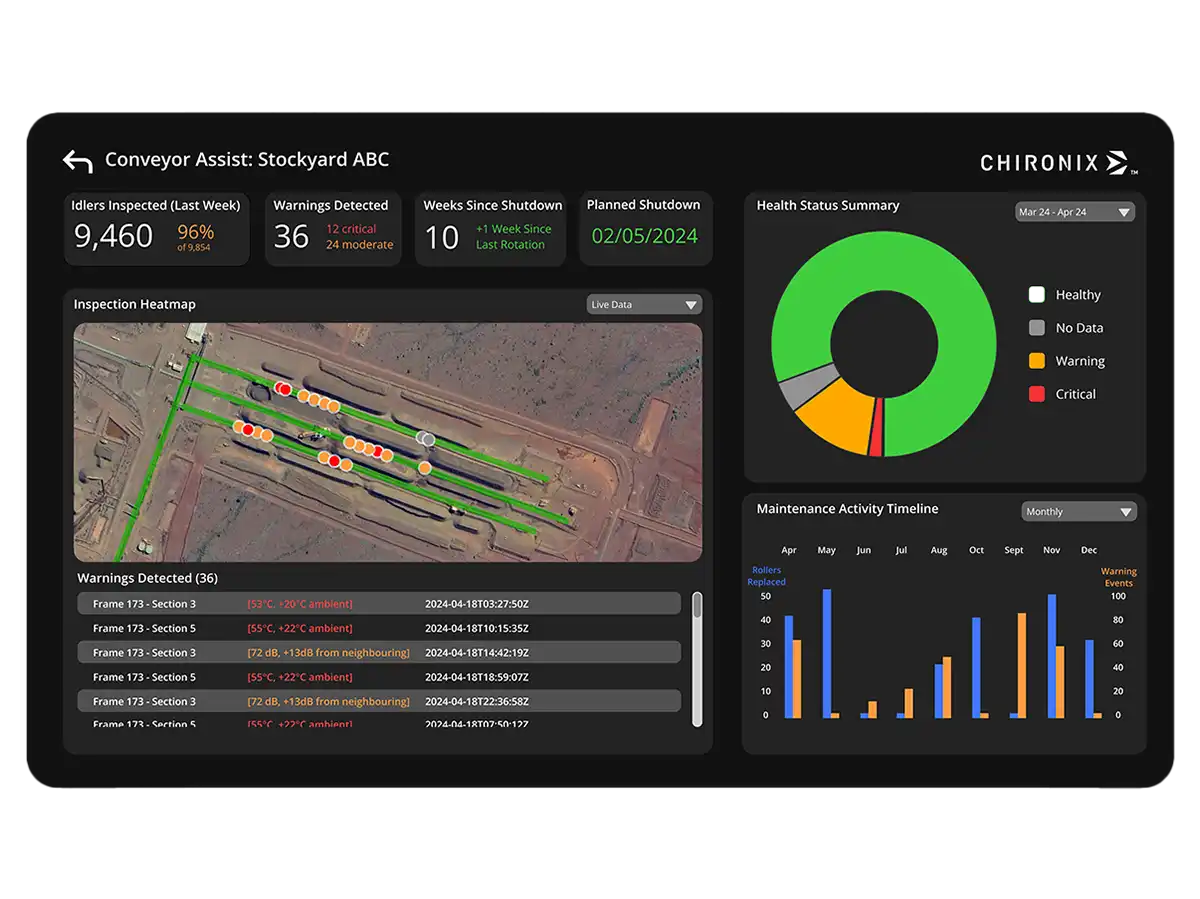

Conveyor and Fixed Asset Inspection

ConveyorAssist is designed to automate the inspection of mining conveyor belts and other fixed assets, offering predictive maintenance insights while reducing the need for manual checks. Key features include:

- Real-time anomaly detection with thermal, visual and acoustic sensors.

- Full autonomy with offline capability, storing up to 1TB of data.

- Set and forget mission programming, or remote control operation for on-the-go flexibility.

- Detailed reports and trend analytics for informed decision-making.

- Uninterrupted operation with onsite charging powered by Starlink.

Safe, Reliable Materials Transport

Transporting heavy loads across mine sites can expose workers to danger. Our autonomous robots take over this responsibility, offering a safe, reliable solution for moving materials like drill sample bags, explosives and equipment.

With a gross 2-tonne payload capacity, PilotOS-enabled robots can safely carry heavy loads across vast areas. These robots allow for pre-programmed routes and real-time monitoring, allowing operators to track movement and ensure successful delivery.

Environmental Data Collection

Our autonomous robots can collect detailed environmental data across vast areas without the need for human presence in hazardous or hard-to-reach locations. Key capabilities include:

- Stockpile Measurements

- Site Surveying

- Site Security

- Environmental Data Collection

- Gas Detection

Deployment and Integration

PILOTOS: THE INTELLIGENCE POWERING YOUR ROBOT TEAMMATES