Intelligent Robotic Automation for Critical Asset Monitoring

With deep expertise in oil and gas, we deliver advanced robotic solutions to optimise remote asset inspection.

Proven in tier 1 onshore and offshore operations, our autonomous robots take over high-risk inspections, reducing manual checks and safeguarding your workforce.

Designed for challenging conditions – from offshore platforms to pipelines and refineries – they navigate hazardous environments, collecting real-time data and turning it into actionable insights.

Predict and Prevent Costly Breakdowns

Preventative Maintenance

Keep Your Teams Safe

Extend Asset Lifespan

Monitor and Assess Site Infrastructure

From offshore rigs to onshore refineries, our autonomous robots take on demanding asset inspections so your team doesn’t have to.

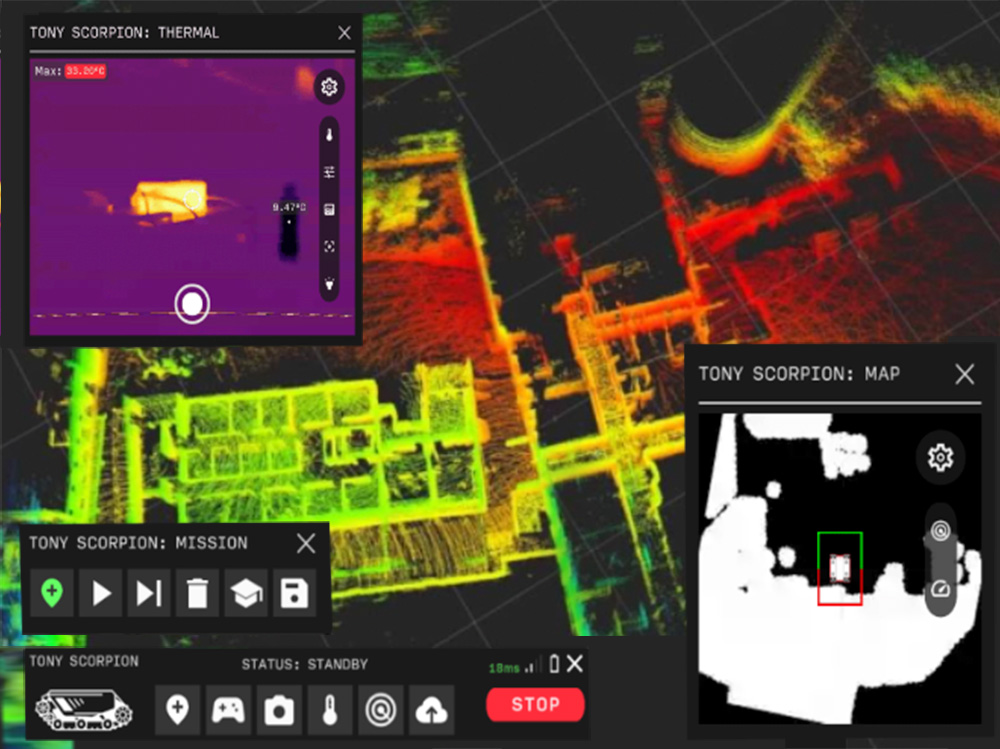

Equipped with thermal, acoustic and visual sensors, they detect corrosion, monitor risk zones and check critical equipment. Remotely monitor and control your robots onsite or from a secure command centre. Get continuous oversight, helping you prevent failures and reduce emergency callouts.

Autonomous Gas Monitoring

Advanced sensors enable rapid detection of gas leaks in large industrial facilities, such as refineries and natural gas processing plants. Early detection is crucial for preventing accidents, safeguarding personnel and minimising environmental risks. Our systems help enhance safety, efficiency and compliance with industry regulations.

Adaptable Mobility For Any Terrain

PilotOS enables precise navigation, allowing robots to easily maneuver through complex oil and gas facilities. The system adapts to real-world challenges, avoiding obstacles and moving through confined spaces.

Operators can track the robot’s location in real time using GPS, live camera feeds and 2D LiDAR maps. Plan missions with ease, considering local terrain for smooth adaptive navigation on site. Set waypoints with a set-and-forget system, with the flexibility to adjust the robot’s path as needed.

Deployment and

Integration

PilotOS: The Brains Behind Your Robot Teammates